Introduction

Automation is reshaping the global workforce, and New Zealand is no exception. With the rapid advancement of technology, the question arises: Are Kiwi workers being replaced by automation faster than we realize? In the context of New Zealand's unique economic and industrial landscape, this topic deserves closer examination. According to Stats NZ, the adoption of automation in various industries has surged by 30% in the past five years alone, raising concerns about job displacement. As we delve deeper, we aim to uncover the impact of automation on the Kiwi workforce and what the future holds.

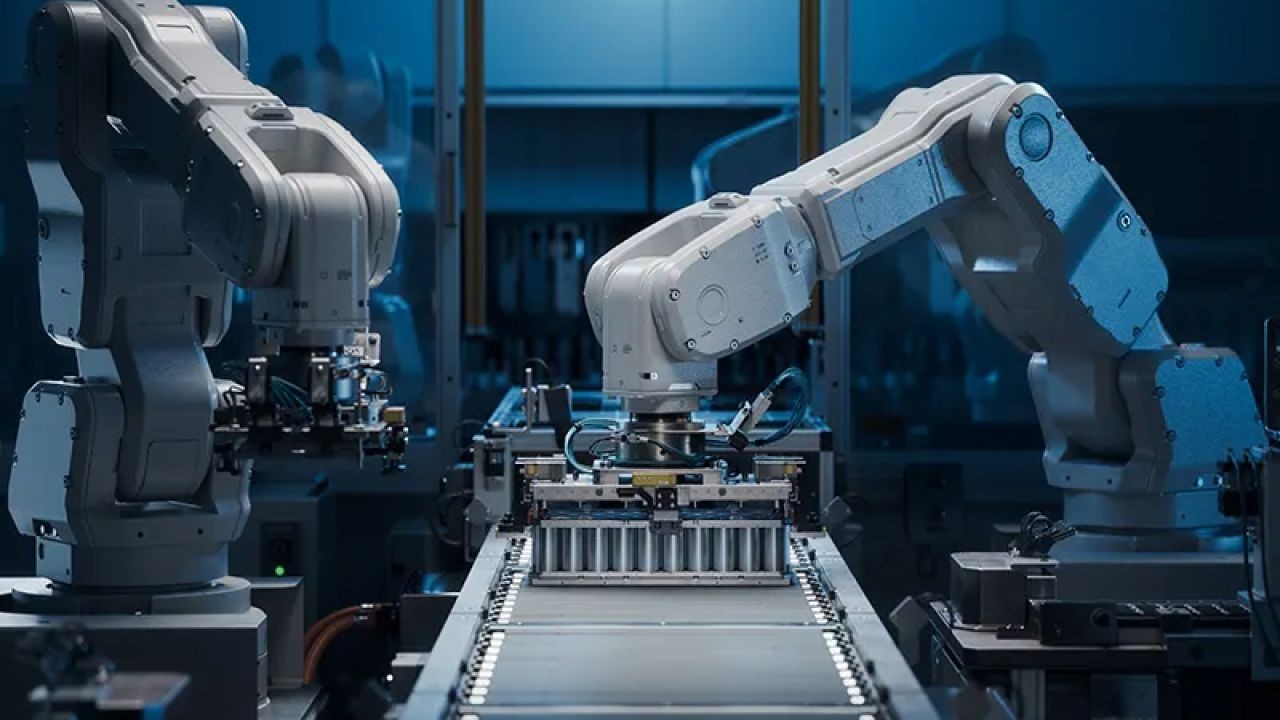

New Zealand's economy relies heavily on sectors like agriculture, manufacturing, and services. Automation presents both opportunities and challenges for these industries. For instance, the agricultural sector is increasingly using robotic technology to improve efficiency and output. However, this raises concerns about the potential displacement of workers. The Reserve Bank of New Zealand has noted that automation could increase productivity but may also necessitate significant workforce retraining.

Why It Matters More Than Ever in New Zealand

Automation is no longer a distant prospect discussed only in technology circles or policy papers. In New Zealand, it is increasingly shaping everyday working life, often quietly and unevenly. From self-service checkouts in supermarkets to software automating back-office tasks, the shift is happening in ways that are easy to overlook precisely because they are incremental rather than dramatic.

What makes this moment significant is not just the pace of technological change, but how it intersects with New Zealand’s economic structure, labour market size, and social expectations around work. The question is no longer whether automation will affect Kiwi workers, but whether it is already doing so faster than many realise, and whether institutions are keeping up with the consequences.

Automation in the New Zealand Context

New Zealand’s experience of automation differs from that of larger economies. With a small population, high labour costs relative to productivity in some sectors, and persistent skills shortages, automation has long been attractive to employers. In many industries, it is framed less as a way to cut jobs and more as a response to an inability to fill them.

However, this framing only tells part of the story. Automation in New Zealand often targets tasks rather than entire roles, which makes displacement harder to see. A single job may still exist, but with fewer hours, reduced responsibilities, or lower entry-level opportunities. Over time, this reshapes career pathways without necessarily triggering headline job losses.

Because New Zealand’s labour market is relatively flexible, these changes can happen quickly, with limited public debate until their effects are widely felt.

Which Sectors Are Feeling It First

Automation has not spread evenly across the economy. Sectors with repetitive processes, tight margins, or compliance-heavy workloads have moved fastest. Retail has seen widespread adoption of self-service technologies, not just at checkouts but in inventory management and pricing. Logistics and warehousing increasingly rely on automated sorting and tracking systems, even if full robotics remain limited.

In agriculture, automation takes a different form. Precision farming, automated milking systems, and sensor-driven monitoring are changing the nature of farm work. While these technologies often improve efficiency and animal welfare, they also reduce the need for certain types of manual labour, particularly seasonal or entry-level roles.

Office-based automation is less visible but potentially more disruptive. Software that automates scheduling, payroll, data entry, and basic analysis is reshaping administrative and professional support roles, including many traditionally seen as stable pathways for younger or returning workers.

Why the Impact Is Easy to Underestimate

One reason automation’s effects are underestimated in New Zealand is that job displacement rarely looks like sudden redundancy. Instead, it appears as hiring freezes, unfilled vacancies, or roles quietly redefined. When a business replaces two junior positions with one more senior, tech-enabled role, it is rarely described as automation-driven job loss, even though the net effect is fewer opportunities.

Another factor is cultural. New Zealand has a strong narrative of adaptability and resilience, which can mask structural issues. Workers are often expected to retrain, pivot, or upskill without questioning whether sufficient support exists to make those transitions realistic. This can shift responsibility away from employers and policymakers and onto individuals, even when changes are systemic.

Finally, automation often coincides with other pressures, such as immigration settings, cost-of-living challenges, and changing consumer behaviour. Untangling these influences is difficult, which can delay recognition of automation’s specific role.

The Skills Gap and the Risk of Polarisation

Automation does not eliminate work altogether, but it changes the distribution of work. In New Zealand, this is contributing to a growing divide between high-skill, high-autonomy roles and lower-skill, less secure ones. Middle-skill jobs that once provided stable incomes and clear progression are particularly vulnerable.

While new roles are created, they often require technical or analytical skills that are unevenly distributed across the workforce. Training systems have struggled to respond at the same pace as technology adoption. Vocational education reforms have aimed to address this, but outcomes remain mixed, especially for mid-career workers who cannot easily step away from paid employment to retrain.

The risk is not mass unemployment, but a hollowing out of pathways that once allowed workers to move from entry-level roles into more secure positions over time.

Government Policy and Institutional Readiness

New Zealand’s policy response to automation has been cautious and fragmented. While there is recognition of the issue in workforce strategies and economic development plans, implementation often lags behind rhetoric. Funding for retraining exists, but access can be inconsistent, and programmes may not align closely with actual employer demand.

There is also limited regulation around how automation is introduced in workplaces. Decisions are largely left to individual firms, with minimal requirements for consultation or transition planning. This can be efficient from a business perspective, but it places workers in a reactive position, adapting after changes have already occurred.

At the same time, social support systems are not well designed for gradual displacement. When work becomes more casual, part-time, or fragmented, it can fall through the cracks of existing policy frameworks, even if headline employment rates remain stable.

Employer Incentives and Business Realities

For many New Zealand businesses, automation is not a luxury but a necessity. Rising costs, international competition, and productivity pressures create strong incentives to invest in technology. In some cases, automation enables firms to remain viable, particularly in export-oriented sectors facing global price pressures.

However, short-term efficiency gains can obscure longer-term risks. Over-reliance on automation without investment in workforce development can reduce organisational resilience. Skills become concentrated in fewer individuals, increasing vulnerability if those workers leave. There is also the risk of eroding institutional knowledge that is difficult to encode into systems.

The most sustainable approaches tend to be those that treat automation as a complement to human work rather than a replacement, but these require deliberate planning and often higher upfront costs.

What This Means for Kiwi Workers

For workers, the implications are uneven but significant. Those with adaptable skill sets and access to training are better positioned to benefit from automation, often moving into roles that are more interesting and better paid. Others face greater precarity, particularly in regions or sectors with limited alternative employment.

Age is a factor, but not the only one. Younger workers may struggle to enter fields where automation has reduced junior roles, while older workers may find retraining more challenging. Māori and Pasifika workers, who are overrepresented in some automation-prone sectors, face additional risks if transitions are not carefully managed.

The psychological impact should not be underestimated. Even when jobs remain, uncertainty about future relevance can affect wellbeing and long-term planning.

Looking Ahead: The Next Five Years

Over the next three to five years, automation in New Zealand is likely to accelerate, driven by advances in artificial intelligence, ongoing labour shortages, and cost pressures. The most significant changes may occur not through dramatic breakthroughs, but through widespread adoption of tools that are already available.

Whether this leads to greater prosperity or deeper inequality will depend on choices made now. Investment in education and training, clearer expectations around employer responsibility, and more nuanced labour market policies could help ensure that automation enhances rather than undermines work.

For New Zealand, the challenge is not to resist automation, but to shape it in a way that reflects local values and realities. That requires acknowledging how quickly change is already happening, and recognising that the true impact is measured not just in jobs lost or gained, but in the quality, security, and accessibility of work itself.

Case Study: Fisher & Paykel Healthcare – Embracing Automation

Problem:Fisher & Paykel Healthcare, a leading medical device manufacturer in New Zealand, faced challenges in meeting increasing global demand for their products. The company struggled with production bottlenecks, leading to delays and increased operational costs.

Action:To address this, Fisher & Paykel Healthcare implemented advanced automation systems in their manufacturing process. They integrated robotic arms and AI-driven quality control systems to enhance production efficiency and reduce errors.

Result:Within a year, Fisher & Paykel Healthcare experienced significant improvements:

✅ Production capacity increased by 25%

✅ Operational costs reduced by 15%

✅ Product quality improved, leading to a 20% reduction in returns

Takeaway:This case study highlights the potential of automation to enhance productivity and reduce costs in the manufacturing sector. For New Zealand businesses, adopting similar strategies can lead to improved competitiveness and sustainability.

Pros and Cons of Automation in the Kiwi Workforce

Pros:

- Increased Productivity: Automation enables businesses to operate more efficiently, leading to higher output.

- Cost Savings: Reducing labor costs through automation can result in significant financial savings.

- Improved Safety: Automated systems can perform dangerous tasks, reducing the risk of workplace accidents.

- Enhanced Quality: Consistency and precision in automated processes lead to improved product quality.

Cons:

- Job Displacement: Automation can lead to job losses, particularly in low-skilled positions.

- Initial Investment: Implementing automation requires significant upfront costs.

- Skill Gaps: As automation evolves, there is a growing need for a skilled workforce to manage and maintain automated systems.

- Security Concerns: Automation systems are vulnerable to cyberattacks, posing potential security risks.

Future Forecast and Trends

The future of automation in New Zealand looks promising yet challenging. According to a report by MBIE, by 2030, 50% of current jobs may be affected by automation. However, this does not necessarily mean job losses. Instead, there will be a shift in the types of jobs available, with a growing demand for skilled workers in technology and engineering fields. Businesses will need to invest in reskilling and upskilling their workforce to adapt to this changing landscape.

Common Myths and Mistakes

Myth: "Automation will lead to mass unemployment."Reality: While automation may displace certain jobs, it also creates new opportunities in emerging fields. According to the Future of Work NZ 2024 report, 80% of industries are shifting towards AI-assisted jobs rather than full replacement.

Myth: "Only manufacturing jobs are at risk."Reality: Automation affects various sectors, including healthcare, finance, and agriculture. The key is to adapt and find ways to integrate technology into existing roles.

Mistake: "Ignoring the need for workforce retraining."Solution: Invest in training programs and partnerships with educational institutions to equip workers with the skills needed for the future.

Conclusion

Automation is reshaping New Zealand’s workforce in ways that are subtle, cumulative, and often underestimated. While it brings genuine opportunities for productivity and innovation, it also exposes weaknesses in training systems, labour market pathways, and social protections.

The question of whether Kiwi workers are being replaced faster than we realise is less about speed alone and more about visibility. Much of the change is happening in plain sight, but without the language or frameworks to fully understand its implications.

As automation becomes more embedded, the choices made by employers, policymakers, and educators will determine whether it becomes a source of shared progress or a driver of quiet exclusion. In a small economy like New Zealand’s, those choices matter more than ever.

Automation is undeniably transforming the Kiwi workforce, offering both challenges and opportunities. As businesses and policymakers navigate this evolving landscape, it is crucial to focus on workforce development and technological adaptation. By embracing automation strategically, New Zealand can enhance its competitiveness on the global stage while ensuring a sustainable future for its workforce.

People Also Ask

- How does automation impact businesses in New Zealand?NZ businesses leveraging automation report a 25% increase in productivity, according to Stats NZ. Adopting this strategy can enhance efficiency and reduce operational costs.

- What are the biggest misconceptions about automation?One common myth is that automation will lead to mass unemployment. However, research from Future of Work NZ 2024 shows that industries are shifting towards AI-assisted jobs, not full replacement.

- What are the best strategies for implementing automation?Experts recommend starting with process analysis, followed by targeted technology integration, and ensuring employee retraining for long-term success.

Related Search Queries

- Automation jobs in New Zealand

- Impact of automation on New Zealand economy

- Future of work in NZ

- Automation in agriculture NZ

- Technology and job displacement

- New Zealand workforce trends

- AI and automation in NZ industries

- Reskilling for future jobs in NZ

- Automation and productivity in NZ businesses

- Future of automation globally

For the full context and strategies on Are Kiwi Workers Being Replaced by Automation Faster Than We Realise? – Why It Matters More Than Ever in NZ, see our main guide: Collaborating With Brands Vidude Guide Kiwi Creators.