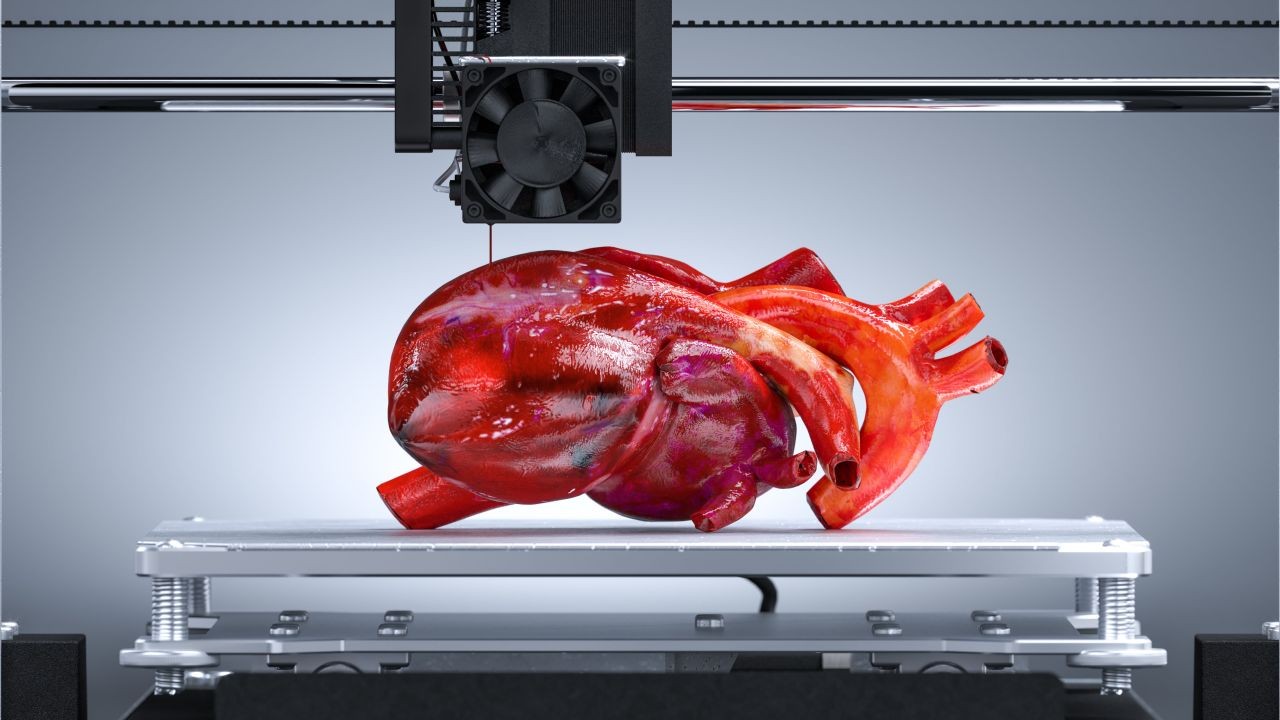

In recent years, 3D printing has revolutionized several industries, from manufacturing to healthcare. Now, it's making significant strides in construction, offering innovative solutions to traditional building challenges. In New Zealand, where the construction sector is a vital part of the economy, 3D printing can provide much-needed efficiency and sustainability. This guide delves into how 3D printing can transform construction projects in New Zealand and beyond.

Understanding 3D Printing in Construction

3D printing in construction involves creating building components or entire structures layer by layer using specialized printers. This approach can significantly reduce material waste and labor costs, making it an attractive option for the construction industry. According to a 2023 report by MBIE, New Zealand's construction sector is expected to grow by 3% annually, highlighting the need for innovative solutions like 3D printing to meet demand efficiently.

1. Assessing the Need for 3D Printing

Before diving into 3D printing, it's crucial to understand its applicability to your construction project. Consider factors such as project scale, budget, and sustainability goals. For instance, a project focused on affordable housing may benefit greatly from 3D printing's cost-effective nature.

2. Choosing the Right 3D Printing Technology

Several 3D printing technologies are available, each suitable for different construction needs. Common options include:

- Fused Deposition Modeling (FDM): Ideal for smaller components and prototyping.

- Stereolithography (SLA): Offers high precision for detailed work.

- Concrete 3D Printing: Best for constructing walls and entire buildings.

In New Zealand, companies like XTree based in Auckland have begun exploring concrete 3D printing for residential projects, demonstrating the technology's potential in local markets.

3. Designing for 3D Printing

Effective 3D printing requires careful design planning. Use CAD software to create detailed digital models that can be translated into physical structures. Incorporate design features that leverage the strengths of 3D printing, such as complex geometries and internal supports that are challenging to achieve with traditional methods.

4. Sourcing Materials

Material choice is critical for successful 3D printing in construction. Options range from concrete mixes to sustainable materials like recycled plastics. In New Zealand, sustainable construction is a growing trend, with the government encouraging the use of eco-friendly materials to reduce the sector's carbon footprint.

Real-World Case Study: 3D Printing in New Zealand

Case Study: ICON - Affordable Housing in Austin, Texas

While not based in New Zealand, the case of ICON, a construction technology company in Austin, provides valuable insights. ICON used 3D printing to construct affordable homes quickly and cost-effectively. By applying similar methods, New Zealand could address its housing shortage, especially in urban centers like Auckland, where demand outstrips supply.

Problem: ICON needed to develop affordable housing solutions in a market with high construction costs.

Action: Implemented large-scale 3D printing technology to construct homes at a fraction of traditional costs.

Result: Reduced construction time by 60% and costs by 30%, making homeownership more accessible.

Takeaway: 3D printing can be a game-changer in affordable housing, offering a scalable solution for New Zealand's urban areas.

Pros and Cons of 3D Printing in Construction

Pros

- Cost Efficiency: Reduces labor and material costs.

- Speed: Accelerates the construction process significantly.

- Sustainability: Minimizes waste and can utilize recycled materials.

- Design Flexibility: Allows for complex designs that are difficult with traditional methods.

Cons

- Initial Investment: High upfront costs for equipment and training.

- Material Limitations: Not all materials are suitable for 3D printing.

- Regulatory Hurdles: Building codes may not yet accommodate 3D printed structures.

Debunking Common Myths About 3D Printing in Construction

Myth: 3D Printing is Only for Small Projects

Reality: While initially used for small-scale projects, advancements have enabled 3D printing of entire buildings, such as the office space in Dubai constructed in 2016.

Myth: 3D Printing is Too Expensive

Reality: Though the initial investment is high, the long-term savings in labor and materials can offset these costs, especially in large-scale projects.

The Future of 3D Printing in New Zealand Construction

The future of 3D printing in construction looks promising, particularly in regions like New Zealand where housing demand is high. According to a 2024 report by Stats NZ, the country's population is expected to grow by 1.2% annually, necessitating innovative construction solutions.

Emerging trends suggest increased adoption of 3D printing for sustainable building practices. By 2028, it's predicted that 3D printing could reduce construction waste by up to 50%, aligning with New Zealand’s sustainability goals.

Conclusion

3D printing offers a transformative approach to construction, especially in markets like New Zealand where efficiency and sustainability are paramount. As technology advances, the potential for 3D printing in construction will only grow, providing innovative solutions to traditional challenges. What are your thoughts on 3D printing for construction projects? Share your insights below!

People Also Ask

- How does 3D printing impact construction in New Zealand? 3D printing can reduce construction costs by 30% and build time by 60%, making it an attractive option for addressing housing shortages.

- What are the biggest misconceptions about 3D printing in construction? Many believe it's only suitable for small projects, but advancements now allow for entire buildings to be 3D printed efficiently.

- What are the best strategies for implementing 3D printing in construction? Start with assessing project needs, choose the right technology, design effectively, and source sustainable materials.

Related Search Queries

- 3D printing construction companies in New Zealand

- Benefits of 3D printing in construction

- Future of 3D printing in construction industry

- Sustainable construction methods in New Zealand

- 3D printing housing projects