For Australian businesses and consumers navigating the electric vehicle transition, a critical question looms beyond the initial purchase price: how will the battery hold up under local conditions? The lifespan of an EV's battery pack is not a fixed number but a complex equation influenced by chemistry, usage, and crucially, environment. In Australia's unique climate—characterised by intense UV exposure, temperature extremes, and vast regional variations—understanding this equation becomes paramount for calculating total cost of ownership, assessing residual values, and planning for the burgeoning second-life battery market.

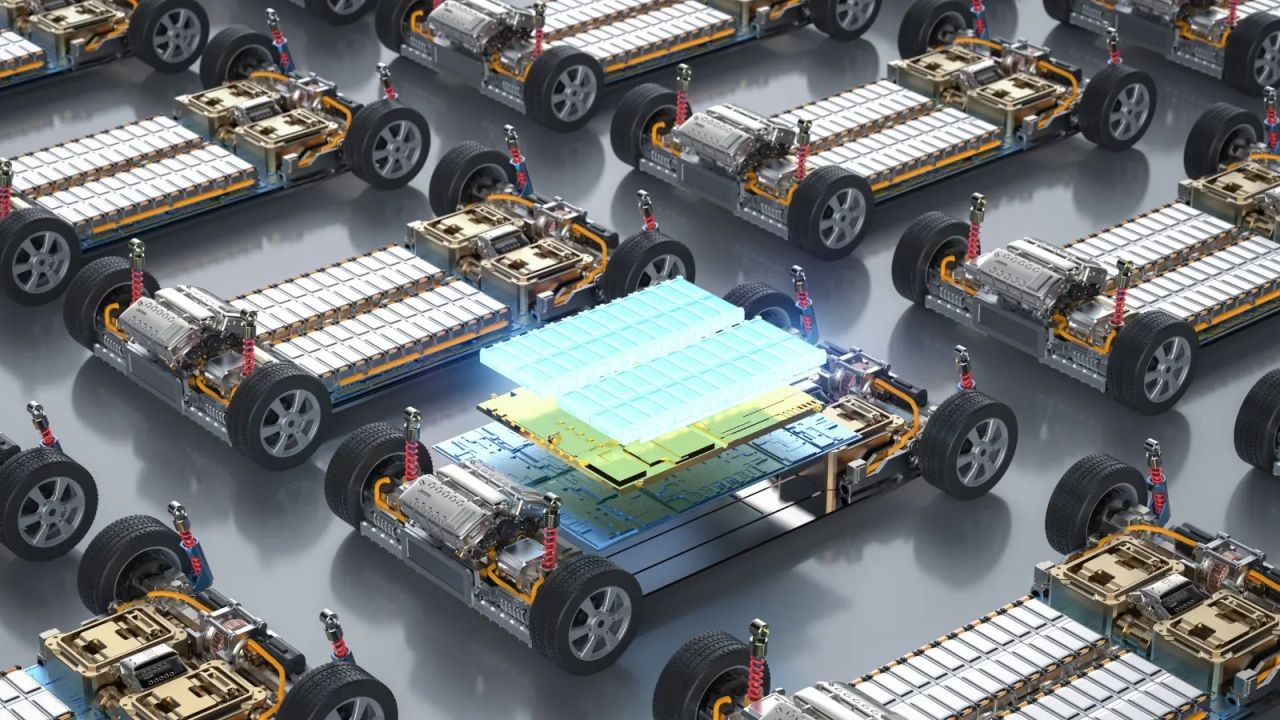

Decoding Battery Degradation: The Science Behind the Capacity Curve

All lithium-ion batteries in EVs experience gradual capacity fade. This degradation is primarily driven by two mechanisms: the growth of a solid-electrolyte interphase (SEI) layer on the anode, which consumes active lithium, and the mechanical stress from repeated charging and discharging that can cause microscopic cracks. The rate of this degradation is exponentially influenced by three key factors: temperature, state of charge, and charging speed.

From consulting with local businesses across Australia integrating EV fleets, the most common oversight is underestimating the thermal factor. Lithium-ion batteries operate optimally within a moderate temperature band, typically between 15°C and 35°C. Consistent exposure to temperatures outside this range, especially sustained heat, accelerates chemical reactions that degrade the battery. A 2020 study by the Australian Automotive Research Centre (AARC) noted that battery packs consistently operating in ambient temperatures above 40°C could see degradation rates up to 30% faster than those in temperate climates, depending on thermal management system efficacy.

Australian Conditions: A Unique Stress Test

Australia presents a distinct set of environmental challenges. The intense summer heat in cities like Perth and Darwin creates a high thermal load, while the strong UV radiation can degrade battery casing materials and cooling systems over time. Furthermore, Australia's vast distances often encourage high-speed, long-distance driving, which demands sustained high power output and frequent use of rapid DC charging—both factors that increase battery stress if not managed properly.

However, it's not a universally negative picture. In my experience supporting Australian companies with fleet transitions, those operating in milder climates like Tasmania or Victoria's high country may see degradation profiles align more closely with favourable European data. The critical differentiator is often driver education and operational protocols, not just geography. A vehicle subjected to daily 100% to 0% charge cycles in Melbourne will likely degrade faster than one in Brisbane managed within a 80-20% state-of-charge window.

Case Study: Australia Post’s Fleet Electrification – Operational Data from the Field

Problem: As a pioneer in electric fleet adoption, Australia Post began deploying electric delivery vehicles (EDVs) in 2017. A key strategic concern was predicting battery lifespan and total cost of ownership across diverse Australian operational environments, from tropical North Queensland to the alpine regions of New South Wales. Unpredictable degradation could severely impact vehicle resale value and lifecycle economics.

Action: Australia Post implemented a rigorous data telemetry system across its EDV fleet, continuously monitoring individual battery pack health, state of charge, charging patterns, and local ambient temperature. Crucially, they established charging protocols that limited maximum state of charge to 80% for daily operations, reserving 100% charges only for routes requiring maximum range. Vehicles were also strategically allocated where possible to align vehicle thermal management capabilities with climate demands.

Result: After five years of operation and millions of kilometres logged, the data revealed compelling insights. Fleet-wide average battery capacity retention exceeded 90%. Vehicles operating in extreme heat showed only a marginally higher degradation rate than the fleet average, attributed largely to the enforced charging protocols and robust vehicle thermal systems. This data provided a solid foundation for scaling the electrification program confidently.

Takeaway: This real-world Australian case study underscores that proactive operational management can mitigate environmental stressors. For Australian businesses, the lesson is clear: invest in fleet management software that monitors battery health and enforce smart charging policies. This operational discipline is as important as the vehicle's technical specifications in ensuring battery longevity.

Strategic Implications for Australian Businesses and Trade

The real-world lifespan of EV batteries directly impacts several key economic areas. For trade specialists, the emerging second-life battery market presents a significant opportunity. A battery with 70-80% residual capacity may no longer be suitable for an EV but holds substantial value for stationary storage applications, such as buffering solar energy in commercial buildings or providing grid stability services. Australia’s world-leading household solar penetration, cited by the Australian Energy Council as exceeding 30% of suitable rooftops, creates a ready-made market for these repurposed units.

Furthermore, battery longevity is a critical factor in the total cost of ownership (TCO) calculations that drive fleet procurement decisions. Drawing on my experience in the Australian market, financiers and leasing companies are now developing more sophisticated residual value models that factor in climate-adjusted degradation rates. Accurate lifespan projections are essential for de-risking these investments and accelerating the commercial EV transition.

Reality Check for Australian Businesses

Several persistent assumptions need correction to inform sound business decisions.

Assumption 1: "Australian heat will destroy EV batteries prematurely." Reality: While heat is a stressor, modern EVs are engineered with sophisticated liquid-cooled thermal management systems specifically to combat this. The operational data from fleets like Australia Post demonstrates that with proper management, batteries can retain health effectively. The greater risk often lies in frequent use of ultra-rapid chargers on hot days, which combines multiple stressors.

Assumption 2: "All battery warranties are the same." Reality: Warranties vary significantly by manufacturer, typically guaranteeing 70-75% capacity retention over 8 years/160,000 km. Crucially, most are not prorated and mandate a replacement if capacity falls below the threshold. Australian consumer law, enforced by the ACCC, provides additional protections. A battery exhibiting excessive degradation outside of normal wear and tear may be considered a major failure, entitling the consumer to a repair, replacement, or refund, regardless of the specific manufacturer warranty terms.

Assumption 3: "You should always charge to 100%." Reality: This is one of the most detrimental habits for long-term health. Lithium-ion batteries are most stressed at the extreme high and low ends of their charge. Based on my work with Australian SMEs, setting a daily charge limit to 80-90% via the vehicle's onboard settings is the single most effective practice to prolong battery life, with full charges reserved for long trips.

Actionable Insights for Maximising Battery Life in Australia

- Leverage Thermal Management: Park in shade or garages where possible to reduce thermal soak. Pre-condition the cabin (cooling or heating) while the vehicle is still plugged in to avoid drawing high power from the battery at extreme temperatures.

- Adopt Smart Charging Habits: Make 80% your daily charge target. Avoid consistently draining the battery below 20%. Where feasible, use AC charging (7-22kW) for overnight sessions instead of frequent DC rapid charging.

- Plan for the Second Life: Businesses investing in EV fleets should develop a long-term strategy for battery health data tracking and eventual repurposing or recycling, aligning with both sustainability goals and potential revenue streams in the circular economy.

The Future: Adaptation and Opportunity

The next five years will see battery technology itself adapt to Australian conditions. Expect wider adoption of lithium iron phosphate (LFP) chemistries, which are more thermally stable and durable (though less energy-dense), particularly in commercial vehicles. Furthermore, the Australian Renewable Energy Agency (ARENA) is funding projects focused on battery recycling and repurposing, which will formalise the value chain for end-of-first-life EV batteries. For trade specialists, this represents a nascent but fast-growing export and domestic industry sector built on a deep understanding of the product's entire lifecycle.

People Also Ask

How does the Australian climate compare to others for EV battery life? Australia's main challenge is sustained summer heat in many regions, which tests thermal management systems. However, its lack of extreme cold winters avoids the severe range loss and battery stress from sub-zero temperatures experienced in markets like Canada or Northern Europe.

What is the real-world battery lifespan I can expect in Australia? Most modern EVs are designed to last the life of the vehicle, typically 10-15 years. With prudent use, retaining 80-90% capacity after 8 years is a reasonable expectation, based on current fleet data. Degradation is non-linear, slowing significantly after the first few years.

Should I buy a used EV in Australia? Yes, but due diligence is key. Request a battery state of health report from the dealer or a qualified technician. Check the vehicle's service history for consistency and consider its prior geographic location. A well-maintained used EV can represent excellent value.

Final Takeaway

The lifespan of an EV battery in Australia is not predetermined by the environment but is a manageable variable. The intersection of smart technology, informed user behaviour, and proactive business planning can effectively mitigate the unique challenges of the Australian climate. For businesses, the focus must shift from fear of degradation to strategic management of a high-value asset throughout its first and second life. The companies that master this will not only reduce their operational costs but also position themselves at the forefront of a sustainable, circular energy economy.

What’s Next? For Australian fleet managers and trade professionals, the immediate step is to integrate battery health analytics into your asset management platform. Start modelling second-life applications for your batteries now, and engage with local research initiatives like those led by the Future Battery Industries Cooperative Research Centre (FBICRC) to stay ahead of the curve in this rapidly evolving field.

Related Search Queries: EV battery degradation Australia heat; second life EV batteries Australia; Australia Post electric vehicle battery data; EV battery warranty ACCC; lithium-ion battery lifespan hot climate; EV fleet management Australia; battery health monitoring software; LFP vs NMC batteries Australia; ARENA battery recycling projects; total cost of ownership electric vehicle Australia.

For the full context and strategies on The Real Lifespan of EV Batteries in Australian Conditions – A Must-Watch Trend in the Aussie Market, see our main guide: Construction Project Videos Australia.