3K Views· 03 September 2024

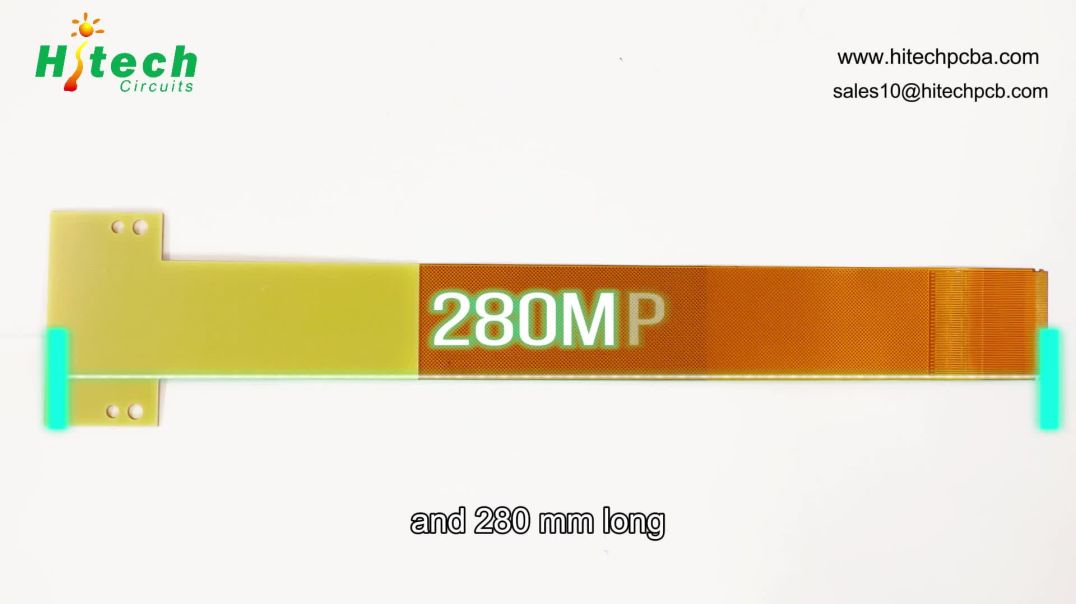

Title: Unlocking Innovation with Flexible PCB Technology by Hitechpcb

Description: Explore the cutting-edge world of Flexible Printed Circuit Boards (FPCBs) in this engaging video by Hitechpcb! Discover how these advanced electronic solutions are revolutionizing industries, from consumer electronics to automotive applications.

Flexible PCBs offer unparalleled design flexibility, reduced weight, and enhanced durability, making them ideal for modern tech innovations. Learn about the manufacturing processes, material options, and applications that make FPCBs a game changer in smart devices.

Whether you're an engineer, designer, or just curious about electronic advancements, this video is packed with valuable insights and tips on leveraging flexible PCB technology for your projects. Don’t miss out on seeing how FPCBs are paving the way for the future of electronics!

#FlexiblePCB #Hitechpcb #PrintedCircuitBoards #Electronics #Innovation #SmartDevices #TechTrends #Engineering

Watch more videos in this category: https://vidude.com/videos/category/other

0 Comments