46 Views· 06 November 2024

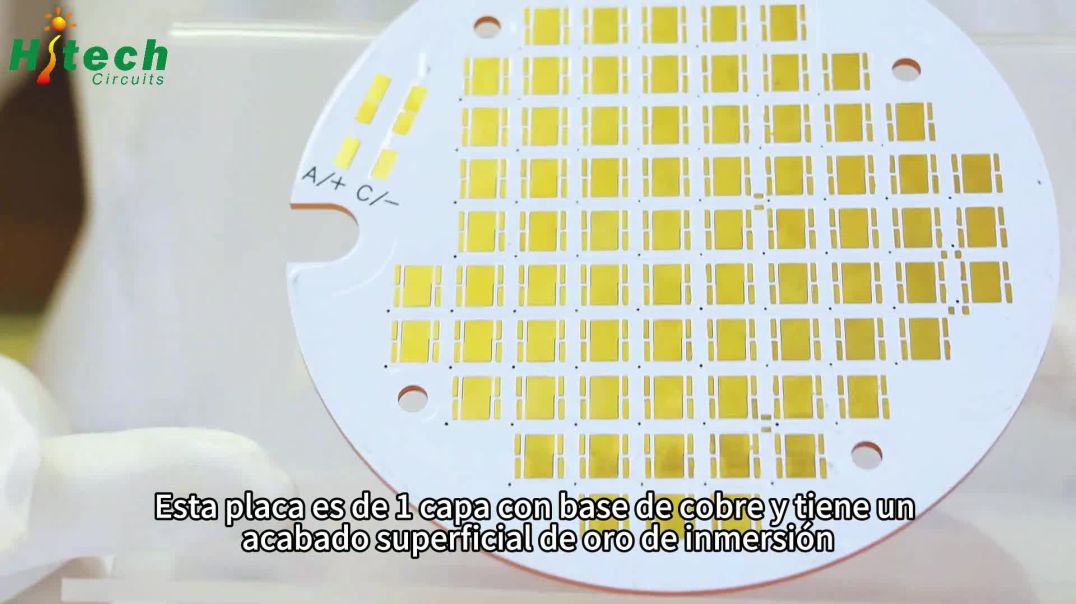

Copper core PCB, Copper based PCB -- Hitech Circuits

Copper-base PCB, Copper core PCB – Hitech Circuits Co., Limited

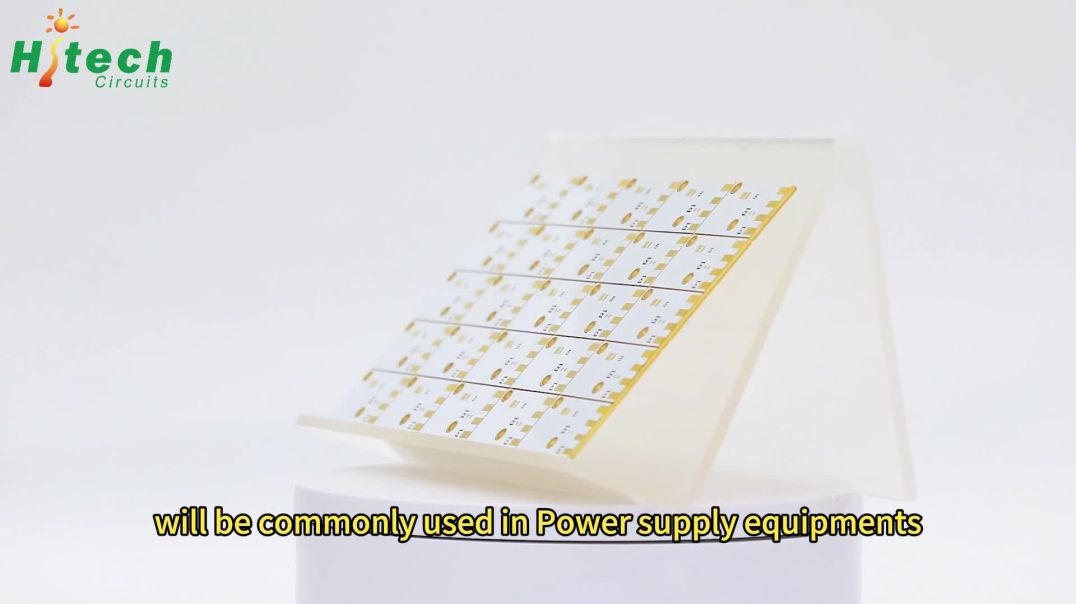

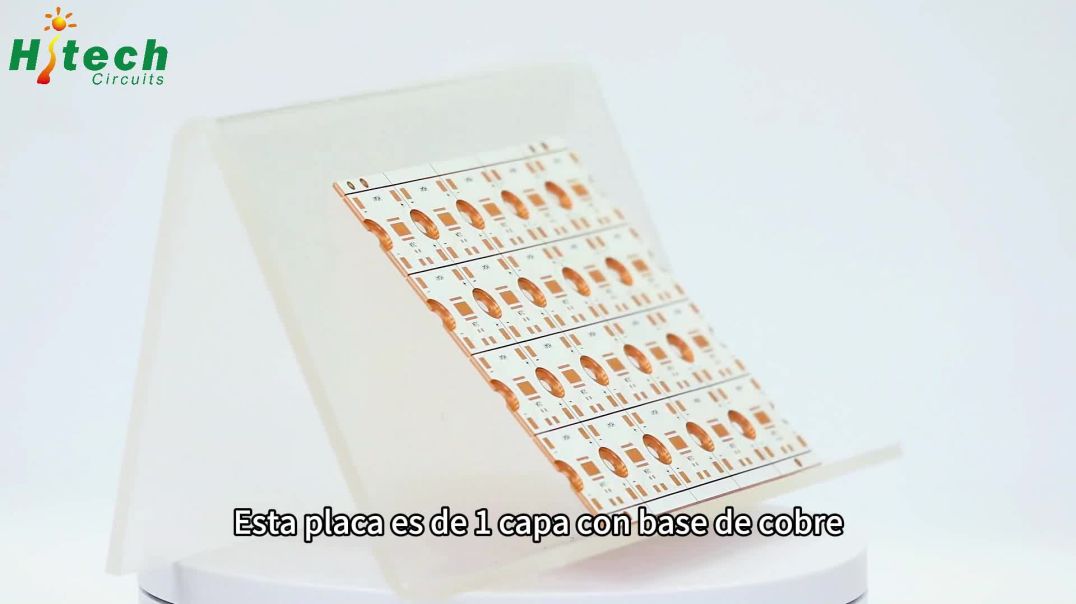

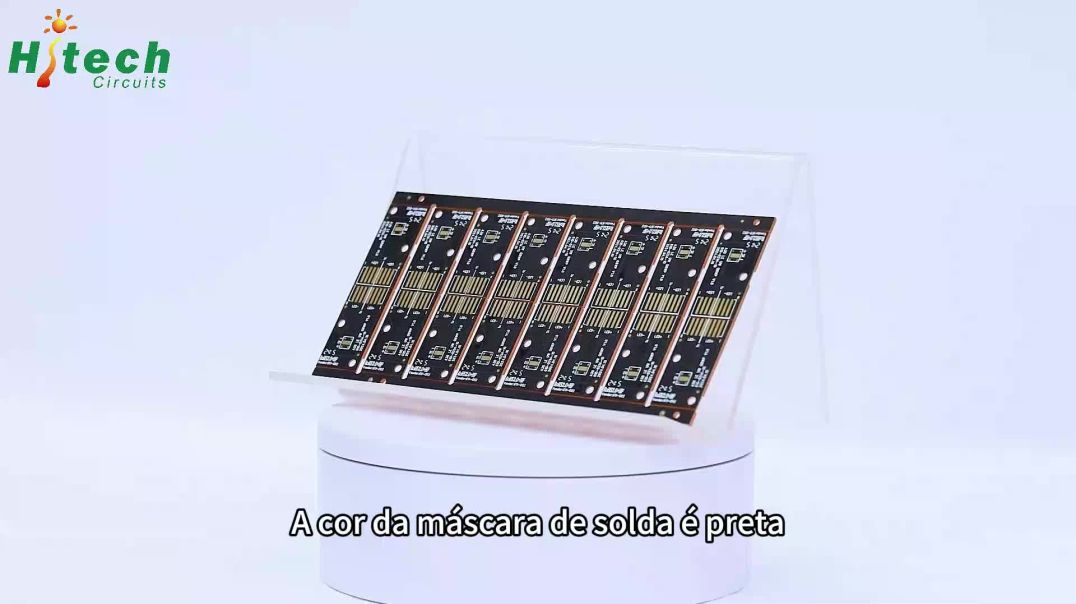

Aluminum PCBs are common insulated metal substrate PCBs (IMSPCB) widely used for LED lights, automotive lighting, and other high thermal conductivity applications. The thermal conductivity of aluminum PCBs is usually 1W/mK or 2W/mK. If an aluminum PCB's thermal conductivity can't satisfy your expected application requirements, why not consider copper-based PCBs?

Copper-base PCBs have better thermal conductivity than aluminum PCBs and provide you with much more design possibilities.

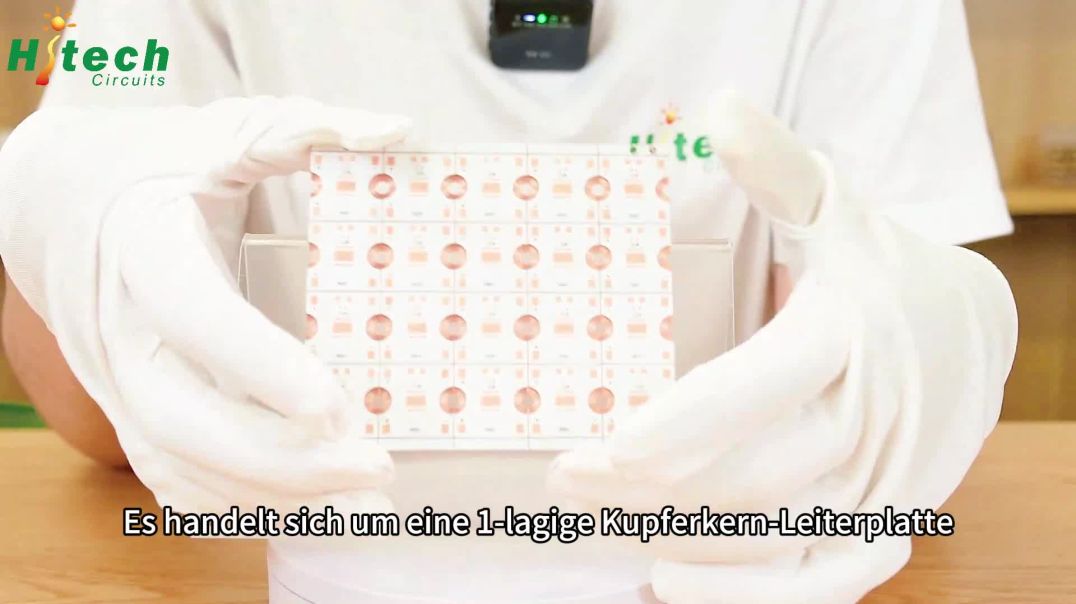

A copper base PCB is a metal core PCB with a copper substrate. If a hybrid PCB whose substrate is a copper plate inlay in the FR4 board, it is also a copper base PCB.

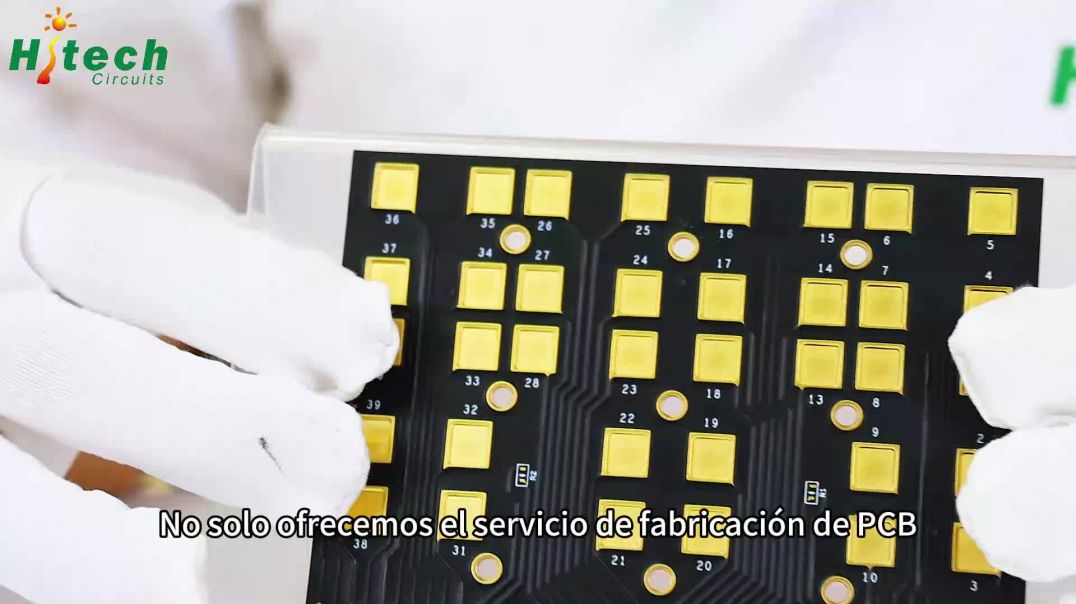

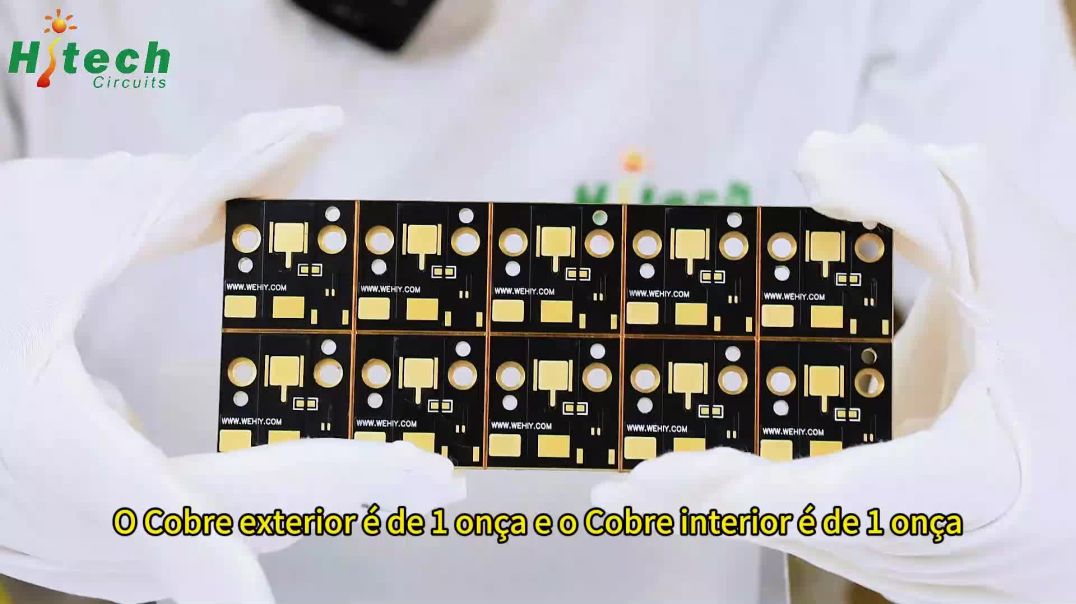

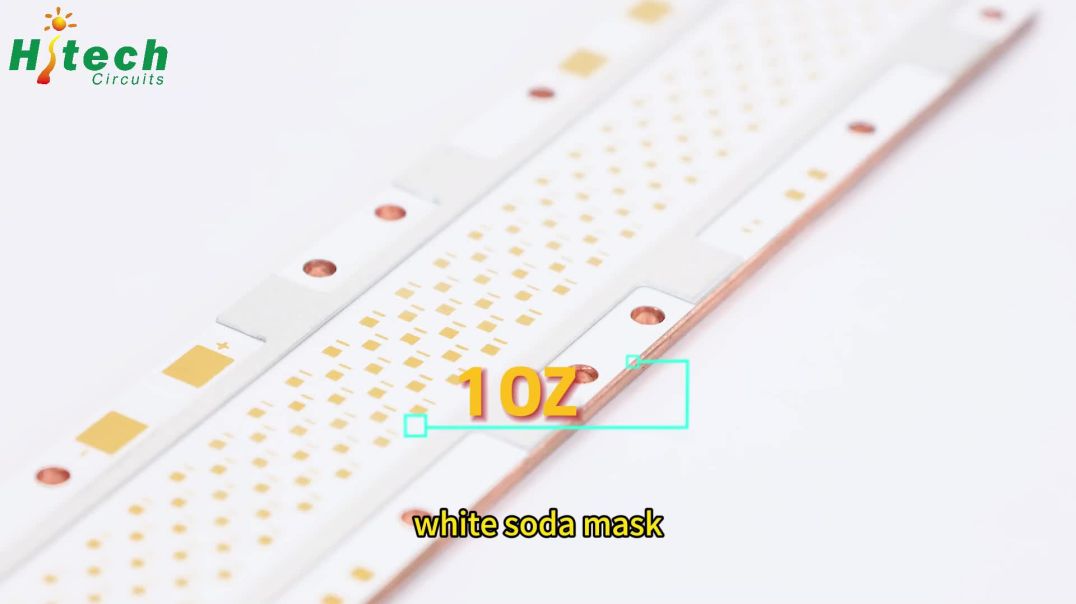

Usually, copper-base PCBs have the same structure as aluminum PCBs - single-layer, double-layer with single component-mounting side, double-layer with dual component-mounting sides, and four-layer with dual component-mounting sides. Even they use the same prepreg material to insulate the copper layers. However, the copper substrate (398W/mK) has better thermal conductivity than the aluminum substrate (237W/mK).

What's more, there's thermoelectric separation technology (also called direct touch technology) for copper-base PCBs. It means by solder mask opening and electroplating copper to increase the copper thickness of required positions, the heat conducts directly from the LEDs or other components to the copper base, while the circuit network is independent of the thermal network.

If you have metal core PCB inquiry, please contact us freely, thanks.

Hitech Circuits Co., Limited

0 Comments